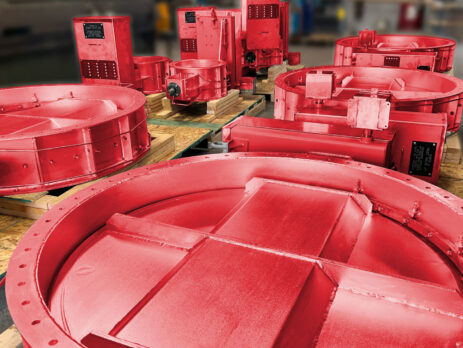

2400 Series Damper with Refractory Lining: Cost-Effective Solution

Refractory lining is a critical feature in high-temperature industrial applications because of its significant benefits in maintaining system integrity and improving operational efficiency. Here’s why it matters: 🔥 Exceptional Heat Resistance and Insulation: Refractory is designed to withstand extremely high temperatures, ensuring that equipment operates safely and effectively under stressful conditions. This makes it indispensable in industries such as metal smelting, chemical processing, and power generation, where thermal processes are intensive. 🛡️ Equipment Protection: By providing a robust barrier, refractory lining shields...