(2700) Weld-In – Heavy Duty

- Description

- Product Specs

- Seat Options

Description

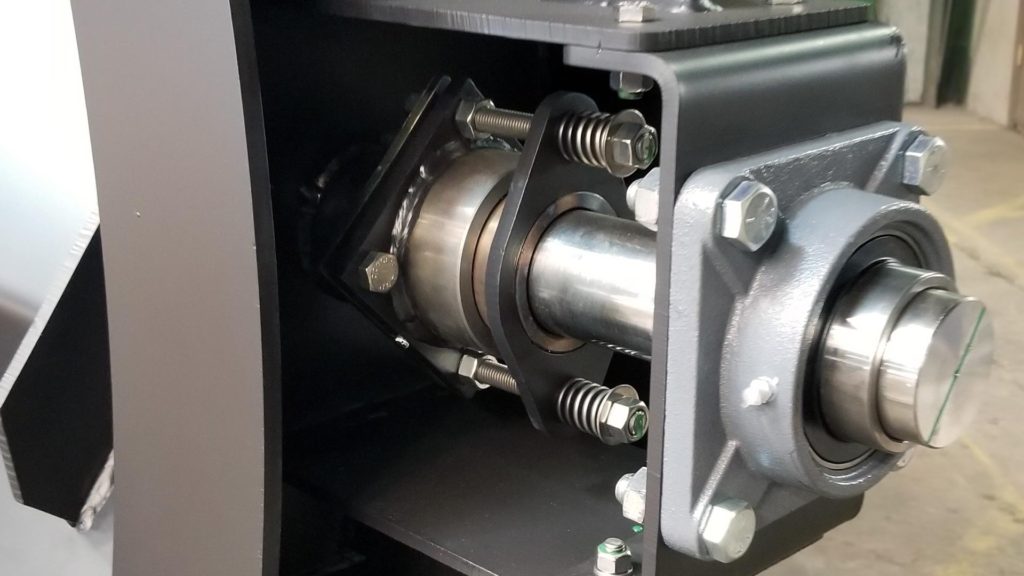

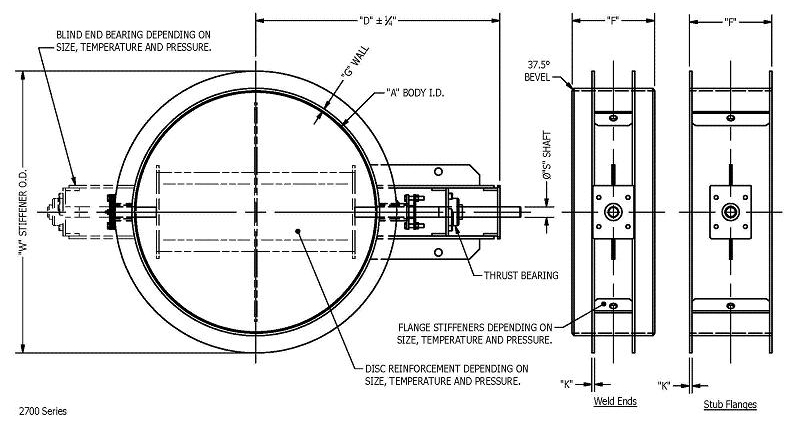

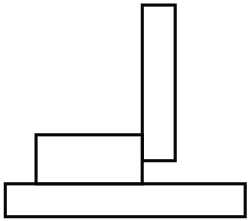

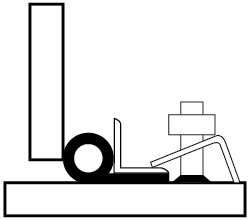

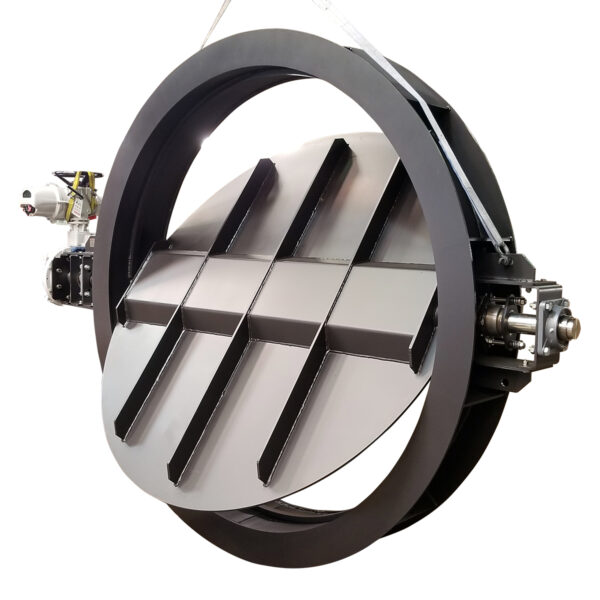

The 2700 series fabricated weld end damper is constructed to be welded in between two duct or pipe sections. Body stiffeners are provided depending on damper size and service conditions. Two types of weld ends are offered. The standard 37-1/2° bevel and the stub end flange for ease of fit-up. Materials of construction are identical to the 2400 series. Damper can be supplied in all weldable materials.

- Sizes up to Ø144″ (Larger and special sizes consult for quote)

- Maximum Operating Temperature: Standard 850˚F, Optional 2,600˚F

- Maximum Static Pressure: 50 PSIG

- Sizes 4″ to 10″ have Sch. 40 wall thickness.

- Blind end bearing standard on size Ø72″ and larger.

- Standard shaft is stub type. Through shaft is available as an option.

- Sizes 4″ to 10″ do not have stiffener rings on weld end (37-1/2 bevel).

Ø84″ 2723-6 Damper Example

Industry Usage

2700 Series News

| Conventional | Scissor Seat | Metal Seat | Tadpole Seat |

|---|---|---|---|

| Swing-thru design, *4-5% leakage | Swing-thru design, approx. *1-2% leakage | Materials same as body - approx. *1% leakage | Material furnished varies with service. Temp. to 2,300˚F, approx. *1/4 of 1% leakage |

|  |  |  |

*Leakage based on damper capacity

2700 Series Round Butterfly Damper Specs

2700 Series Round Butterfly Damper Specs