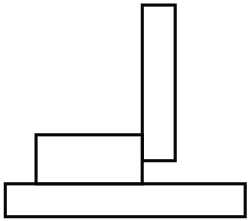

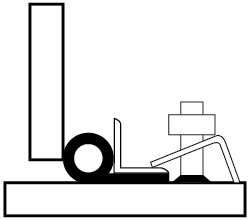

(2600) Diverters

- Description

- Product Specs

- Seat Options

Description

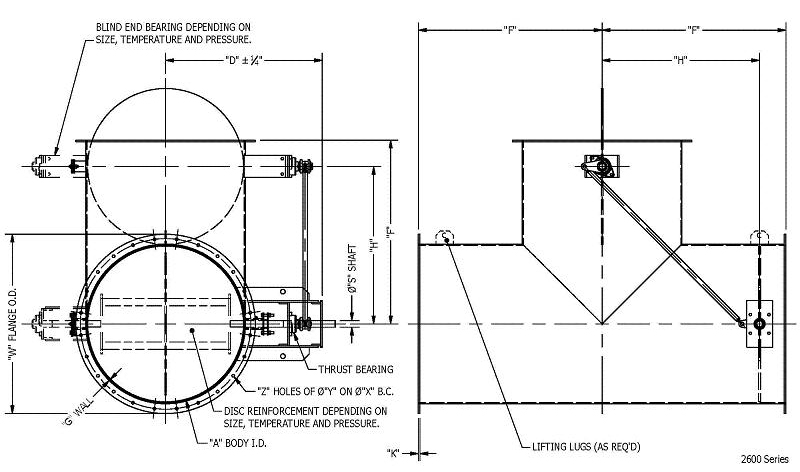

Our Tee and Wye dampers are designed to give long, trouble free service in all low pressure service applications. The versatility of the fabricated Tee and Damper allows to design to your specifications as required by your systems.

- Sizes up to Ø96″ (Larger and special sizes consult for quote)

- Flanges, Body & Disc: Standard – Carbon Steel, Optional – A-588, Stainless Steel, Exotic Materials & Refractory Lines Available on Request

- Shaft: Standard – Stainless Steel, Optional – Various Stainless Steel & Exotic Materials

- Bushings: Standard – Carbon Graphite (3,000°F), Optional – Bronze, Teflon & Nitronic 60

- Bearings (Outboard ball): Standard – Ø72″ & above (Std. w/ seat), Optional – Ball & roller (all sizes)

- Packing Follower: Standard – Stainless Steel, Optional – Same alloys as body

- Lantern Gland: Standard – Carbon, Optional – Same alloys as body

- Seat: Standard – Swing-through, Optional – Scissor, Metal & Tadpole

- Maximum Operating Temperature: Standard 750°F, Optional 2,100°F

- Maximum Static Pressure: Standard 5 PSIG, Optional 150 PSIG

- Maximum Shut-Off Pressure Drop: Standard 1 PSI, Optional 50 PSI

- ANSI drilled flanges with various thicknesses available.

- Outboard bearing on blind end available.

- Flange thickness based on size and service.

- Rolled angle flanges available on medium duty low temperature, low pressure applications.

- Flanged or weld ends.

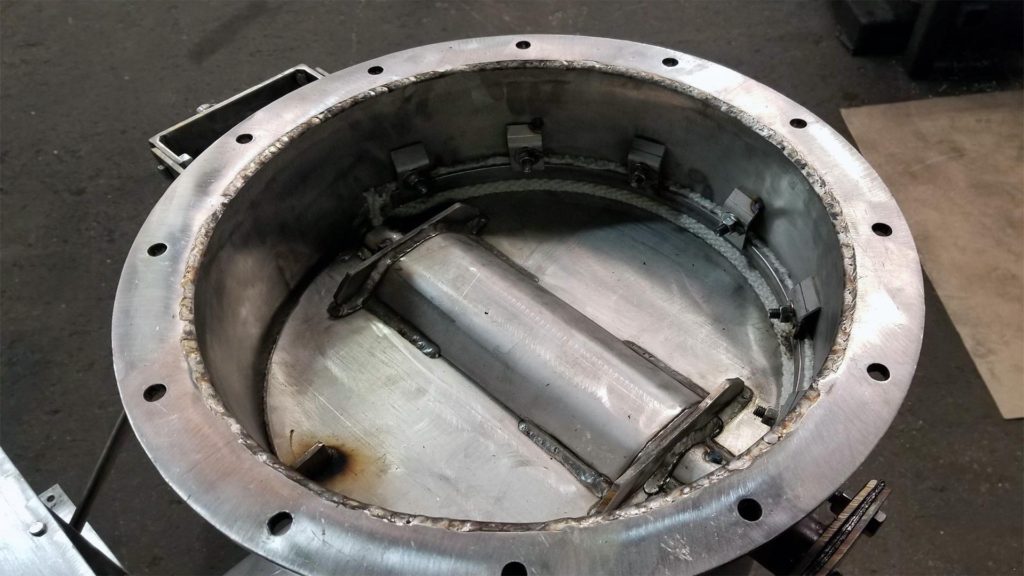

Ø16″ 2623-8-8 Diverter Example

Industry Usage

2600 Series News

| Conventional | Scissor Seat | Metal Seat | Tadpole Seat |

|---|---|---|---|

| Swing-thru design, *4-5% leakage | Swing-thru design, approx. *1-2% leakage | Materials same as body - approx. *1% leakage | Material furnished varies with service. Temp. to 2,300˚F, approx. *1/4 of 1% leakage |

|  |  |  |

*Leakage based on damper capacity

2600 Series Tee Damper Specs

2600 Series Tee Damper Specs