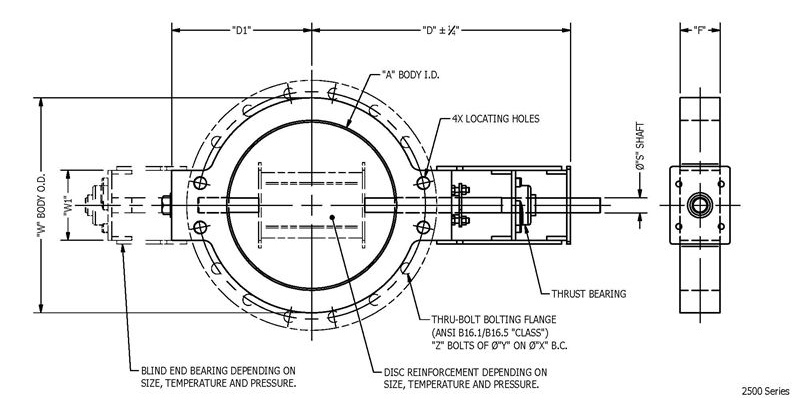

(2500) ANSI Class “Lugged” Wafer

- Description

- Product Specs

- Seat Options

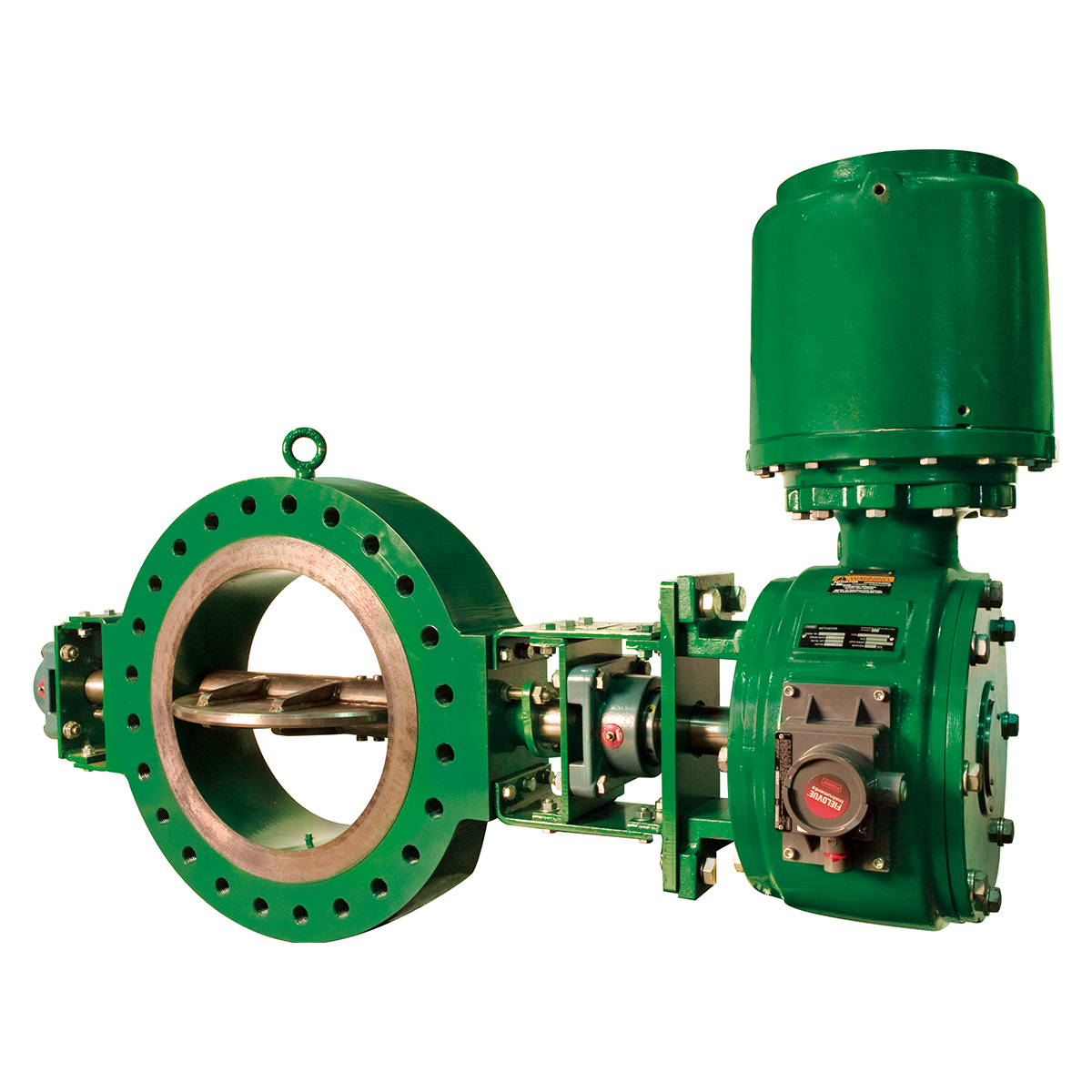

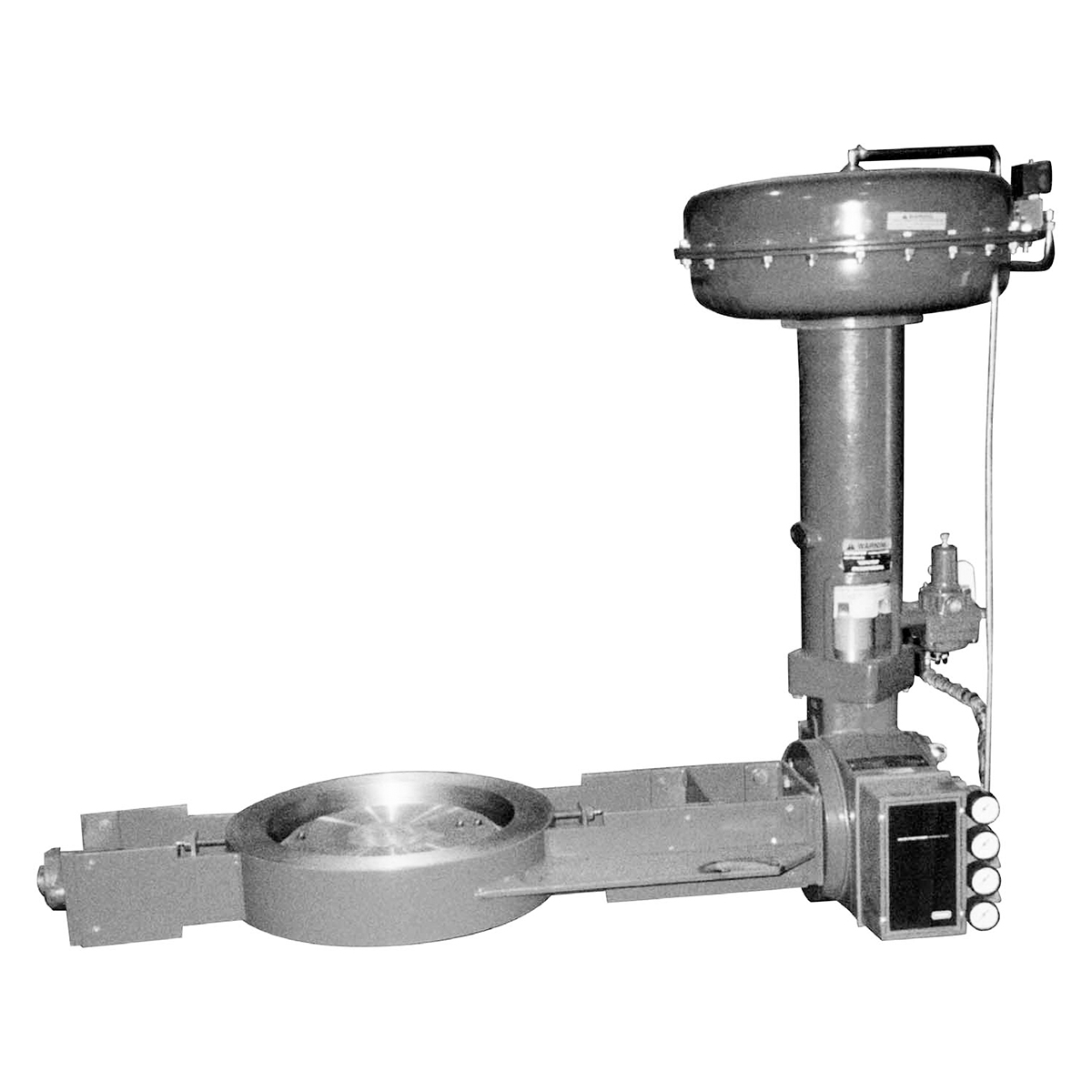

Description

The 2500 body is a durable, solid ring type body that is machined for accurate disc alignment. Standard body wall thicknesses vary according to static pressure and flange rating. The body is designed to with-stand stresses imposed upon it, through pipe flanges. Each disc is fabricated with precision machined and specially finished tolerances preventing shaft distortion and disc misalignment. Ample metal is provided in the hub to maintain rigidity and strength of the disc and its components. The shaft cam be either one piece or stub shafts. Bolting holes are located in valve body where optimum strength requirements provide maximum support to the total valve assembly. Two or four body holes are dimension according to USAS Code flange standards depending on valve size.

- Sizes up to Ø72″ (Larger and special sizes consult for quote)

- Body & Disc: Standard – Carbon Steel, Optional – A-588, Stainless Steel, Exotic Materials Available on Request

- Flange Rating: Standard – 125/150#, Optional – 300, 600, 900, 1500 & 2500# ANSI

- Shaft: Standard – Stainless Steel, Optional – Various Stainless Steel & Exotic Materials

- Bushings: Standard – Carbon Graphite, Optional – Bronze, Teflon & Exotic Materials

- Bearings (Outboard ball): Standard (none), Optional – Ball & roller

- Packing Follower: Standard – Stainless Steel, Optional – Same alloys as body

- Lantern Gland: Standard – Stainless Steel, Optional – Same alloys as body

- Maximum Operating Temperature: Standard 750°F, Optional 3,000°F

- Maximum Static Pressure: 50 PSIG (depending on size), Optional 2,500

- Maximum Shut-Off Pressure Drop: Up to 20 PSI (depending on size), Optional 300 Max.

Industry Usage

2500 Series News

| Conventional | Scissor Seat | Metal Seat | Tadpole Seat |

|---|---|---|---|

| Swing-thru design, *4-5% leakage | Swing-thru design, approx. *1-2% leakage | Materials same as body - approx. *1% leakage | Material furnished varies with service. Temp. to 2,300˚F, approx. *1/4 of 1% leakage |

|  |  |  |

*Leakage based on damper capacity

2500 Series Round Butterfly Damper Specs

2500 Series Round Butterfly Damper Specs