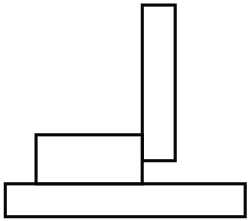

(2200) ANSI Fabricated Wafer

- Description

- Product Specs

- Seat Options

Description

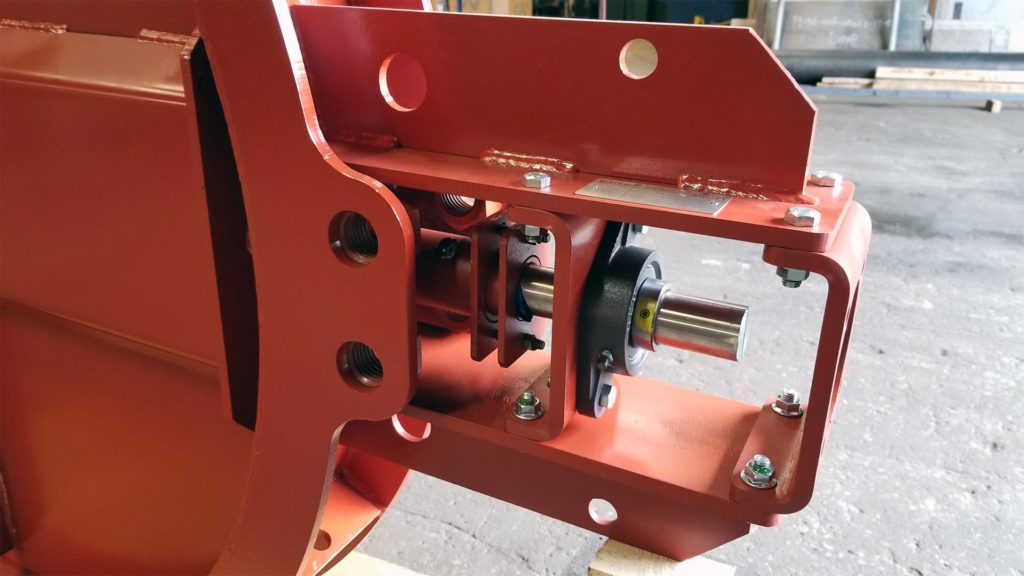

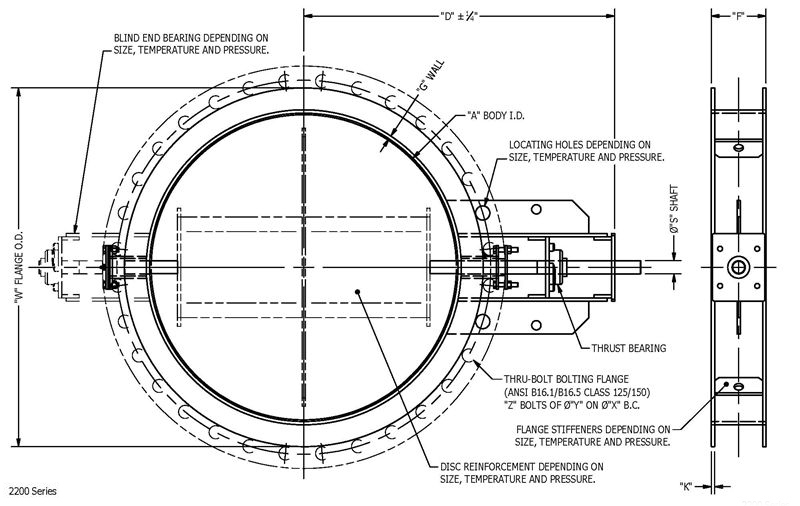

The 2200 series fabricated wafer damper is constructed to fit between 125/150# ANSI flanges with sizes up to Ø72″. Locating holes are provided to center damper in the pipeline. Flange stiffeners are provided depending on damper size & service conditions. Flange faces are standard mill finish. Machined / serrated flanges can be provided as an option. Materials of construction are identical to the 2400 series. Damper can be supplied in all weldable materials.

- Sizes up to Ø72″ (Larger and special sizes consult for quote)

- Maximum Operating Temperatures: Up to 2,100°F standard, up to 2,600°F are optional

- Maximum Static Pressure: 50 PSIG

- Blind end stuffing box and blind end outboard ball bearing available as an option.

- Standard shaft is stub type. Through shaft is available as an option.

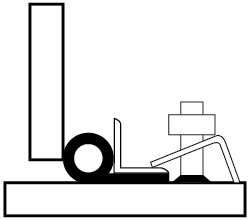

Ø54″ 2220-8-S Damper Example

Industry Usage

2200 Series News

| Conventional | Scissor Seat | Metal Seat | Tadpole Seat |

|---|---|---|---|

| Swing-thru design, *4-5% leakage | Swing-thru design, approx. *1-2% leakage | Materials same as body - approx. *1% leakage | Material furnished varies with service. Temp. to 2,300˚F, approx. *1/4 of 1% leakage |

|  |  |  |

*Leakage based on damper capacity

2200 Series Round Butterfly Damper Specs

2200 Series Round Butterfly Damper Specs