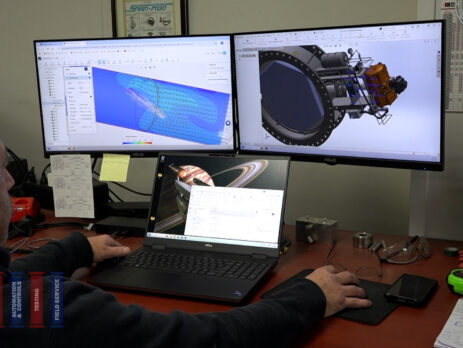

Why Replace When You Can Refurbish?

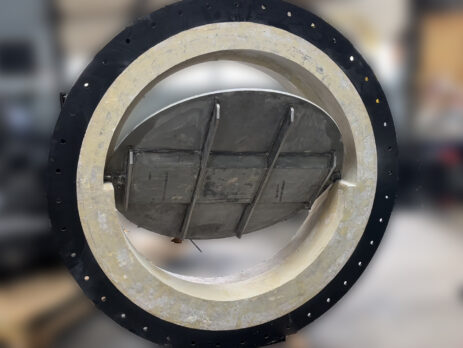

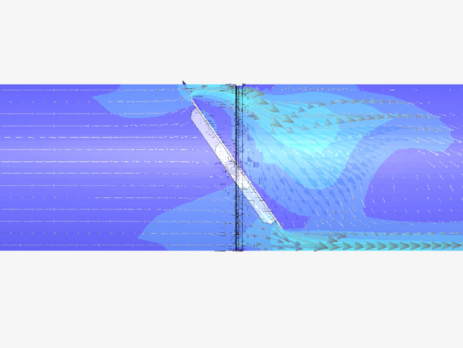

We recently refurbished two Shan-Rod 48” 2400 Series Heavy Duty Ductwork Drill Dampers. These dampers have been in line since 1993, enduring over three decades of continuous service. You can see the wear, weather, and time taking their toll 𝗮𝗳𝘁𝗲𝗿 𝟯𝟮 𝘆𝗲𝗮𝗿𝘀 𝗼𝗳 𝘀𝗲𝗿𝘃𝗶𝗰𝗲. However, after a thorough inspection, we determined that refurbishment was the smarter solution over full replacement—offering faster turnaround times, cost savings, and a more sustainable approach to damper maintenance. Through our Inspect & Advise Program,...