Mining and Mineral Processing

Mineral processing, also known as ore dressing, is the art of treating raw ores and the process of separating commercially valuable minerals from their ores. Our valve and damper solutions allow the analysis of material, comminution, crushing/grinding and creating a raw concentration of material. We supply solutions for every step of the mining operation.

When our customer starts mining for a more concentrated material it is then carried via various conveyors and lift systems to be processed through our 2700 series weld-in heavy duty damper. The 2700 series construction allows more "wear-and-tear" with raw minerals contacting the internals of the damper and function without issue.

Petrochemical

Petrochemicals, also known as petroleum distillates, are chemical products obtained from petroleum by refining. Various chemical compounds made from petroleum are also obtained from other fossil fuels, including coal or natural gas, or renewable sources such as maize, palm fruit or sugar cane. Oil refineries and chemical plants need to have absolute control of the flow of media and exhaust of machines within the facility. The valve or damper can be modulating or open/close to restrict flow, divert flow to process various batches at once, and/or open exhaust ventilation to lower temperature in the line.

We have various models that can fit your application in terms of what your project requires. Our 2700 series weld-in heavy duty damper allows a larger amount and higher temperature media to be processed at once. If diverting of media is required our 2600 tee-diverter will allow immediate deviation when needed. If you require a square/rectangular valve our 3200 series single blade & 3400 series multi-louver allows for the perfect solution.

Iron and Steel

The iron and steel industry has become a staple of the world's economy with all other industries depending on it for their machinery. This includes the defense, transportation and heavy engineering and energy and construction industries. There are two main types of steel mills we supply our damper models to: traditional large integrated steel mills (metallic iron from ore) and specialty steel mill (produces new steel products by melting steel scrap). The dampers provided for these applications need to withstand large amounts of heat to move any molten material through an active line.

We primarily provide our 2300 series ANSI drilled heavy duty damper or 2400 series ductwork drilled heavy duty damper depending on whether the steel mill has standard mounting or custom bolt patterns. Each valve can have a custom bolt hole pattern if required and is not restricted to standard sizes.

Glass Production

Glass container factories are mostly divided into three-part operations: the batch house (initial step that houses the raw materials in large silos), the hot end (location where the molten glass is manufactured into specific glass products), and the cold end (complete the final tasks in the manufacturing process). Our various models of dampers have been installed on multiple operations throughout glass container factories.

Our 2100 series ductwork drilled medium duty damper allows for materials to be moved through an active line, allowing exhaust from furnaces and various processing modulating or open/close application. One customer in particular uses a uniquely configured 2100 series damper to improve efficiency of their machines during production. We have also provided our 5000 series bonneted gate valve to hold and control flow of material from storage silos.

Pharmaceutical

Pharmaceutical manufacturing is the process of industrial-scale synthesis of pharmaceutical drugs as part of the pharmaceutical industry. The process is broken down into various series of unit operations, such as milling, granulation, coating, tablet pressing, etc. The various chemicals being used need to be sent through an active line that is resistant to build up and can withstand break down from the chemical compound.

Our 2100 series ductwork drilled medium duty damper is offered in various grades of material including stainless steel to withstand harsh and hazardous materials required in production.

Automotive Manufacturing

The automotive industry is one of the world's largest by revenue. A sub-section of the automotive industry is automotive manufacturing for mass production of various vehicle makes and models. One primary use of our 2400 series ductwork drilled heavy duty dampers in an automotive plant is to process the active paint line. Our dampers are designed to withstand the paint actively flowing through and when closed to not seize up from the paint drying in the line. We've worked with the Ford Motor Company™ and Mercedes-Benz™ in various manufacturing plants around the country.

Industrial Construction

The construction industry has two main categories for building construction: residential and industrial. We have provided our 2300 series ANSI drilled heavy duty damper to various construction equipment companies including Caterpillar, Inc (CAT™). This has been used for testing equipment on site for various projects and applications with new construction.

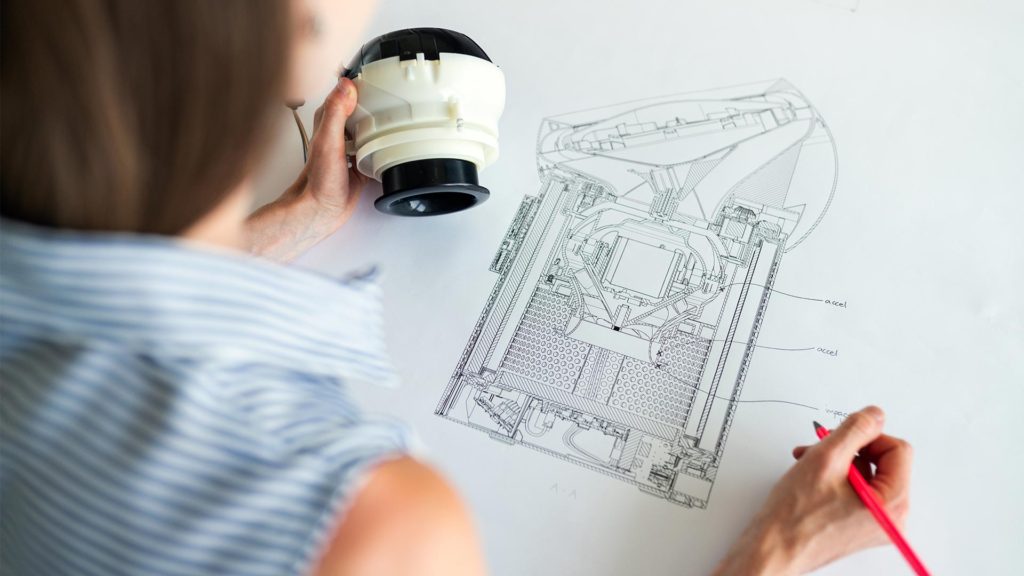

Engineering Collaboration

We have worked with a large variety of companies including engineering firms, designing concepts for use in customer projects. Working directly with the engineering firms and their customer ensures the damper/valve will meet the required application without issue. One example of this collaboration would be our 5000 series bonneted gate valve that a customer requested for a specific location with tight restrictions. We were able to work with them to modifying our standard design to fit perfectly.

Pulp and Paper

The pulp and paper industry contains companies that use wood as raw material and produce pulp (chemically or mechanically separating cellulose fibers), paper (processed cellulose fibers draining water through fine mesh weaving), paperboard (thick paper-based material) and other cellulose-based products. Pulp is fed into a machine where its formed by removing water by pressing and dried using heat.

Our 2200 series ANSI fabricated wafer damper is used to exhaust the steam from the machines used to dry paper while withstanding maximum operating temperatures up to 2600°F. This allows the release of the built up temperature within the machines and to cool easily when processes are completed.

Food Processing

Food processing is the transformation of agricultural products into food, or of one form of food into other forms. This can include grinding grain to make raw flour for home cooking to complex industrial methods used to make convenience foods (commercially prepared). Primary food processing is required to make most foods edible, and secondary food processing turns the ingredients into familiar foods, such as bread.

Our 2100 series ductwork drilled medium duty damper is a perfect solution for the food processing industry: it comes with a standard size bolt pattern that is used across many industries and can withstand operating temperatures up to 1,000°F.

Industrial Chemical

The chemical industry converts raw materials (oil, natural gas, air, water, metals and minerals) into more than 70,000+ different products. The plastics industry fits within this overlap as some chemical companies produce plastics as well. As of 2018 the chemical industry comprises approximately 15% of the US manufacturing economic sector.

Our 2400 series ductwork drilled heavy duty damper is offered in various grades of material including stainless steel to withstand the harsh and hazardous materials used in production.

Government & Military

The United States Military has been a customer of our 4100 series EV-O-Seal for various orders. Tooele Army Depot installed various sizes including from Ø24" up to Ø48" in their base for flue gas exhaust. The bubble tight shut-off was a must have in their current application. Our 4100 series features a double disc for redundant bubble tight (optional) shut-off in the event of a seal being damaged, airfoil reinforced disc (optional), an easy replacement of seal on sizes Ø48″ and larger without removing the valve from the line and a positive system isolation in positive or negative pressure systems.

Energy Production

Elite is not shy when it comes to supplying heavy duty valves to the energy industry. This includes various industries involved win the production and sale of energy, including fuel extraction, manufacturing, refining and distribution. This is essential in todays modern society of various dependencies on fossil fuel looking to alternatives in the electrical power, nuclear power and alternative energy.

Our 4300 series features a bubble tight shut-off with combined scissors/inflatable seat, double disc for redundant bubble tight shut-off in the event of seal damage, airfoil reinforced disc (optional), an easy replacement of seal on sizes 36″ and larger without removing valve from the line, positive seal inflation when disc in closed position, and deflation before disc opening and bubble T.S.O. service.