Fully Automated Dampers and Valves with Complete Turnkey Solutions!

Since taking over the Shan-Rod brand on May 1st, 2019, Elite Industrial Controls has been improving manufacturing processes, reducing overall production costs, investing in machinery and tooling to provide new techniques in fabrication and increases the number of employees to achieve customer requested deadlines. At Elite, we never stop innovating. It’s our nature to continuously improve and evolve to be the best we can possibly be as a company and individuals. We have implemented weekly product reviews, invested in research & development and receptacle to valuable customer criticism allowing for new product lines.

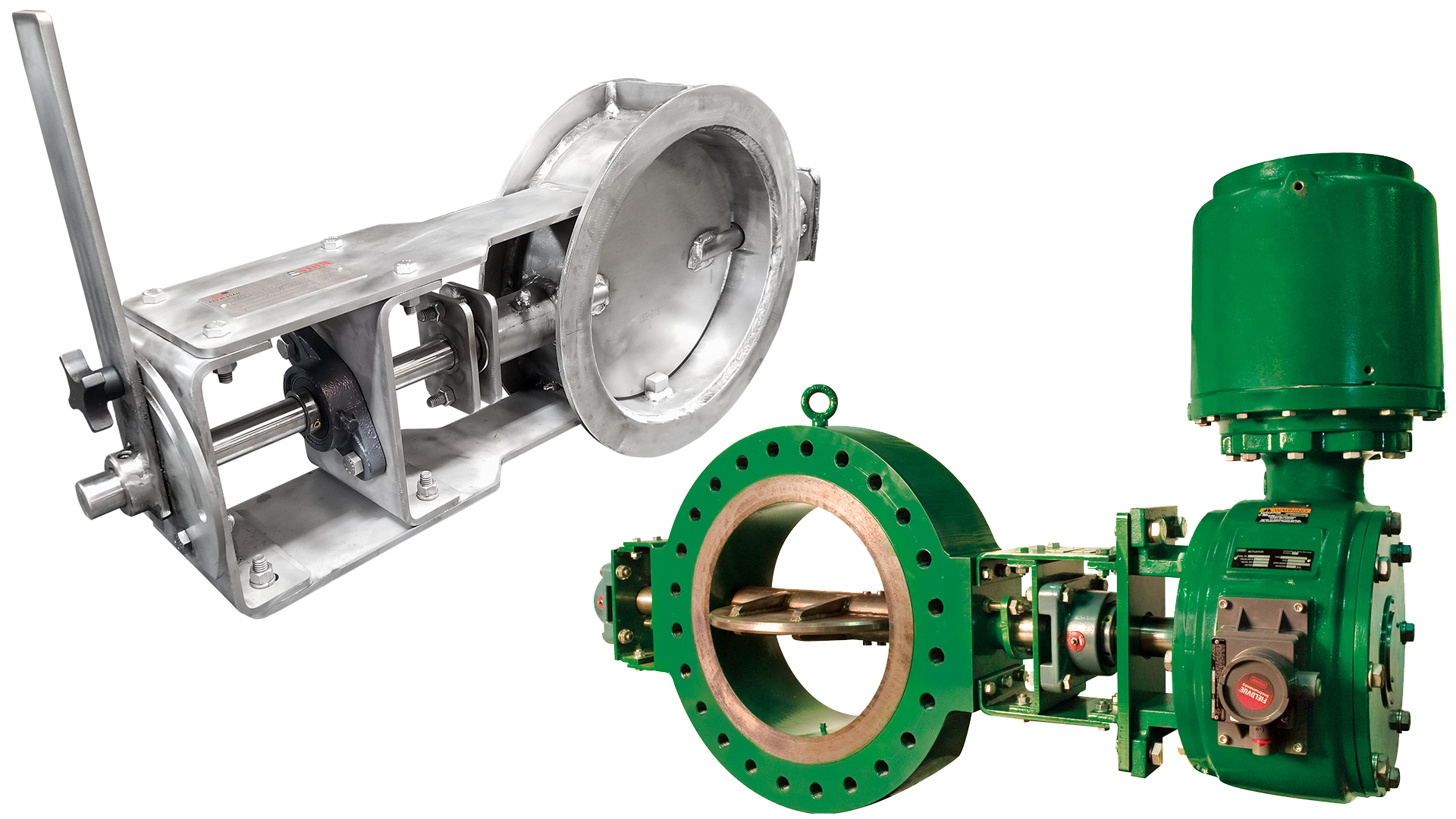

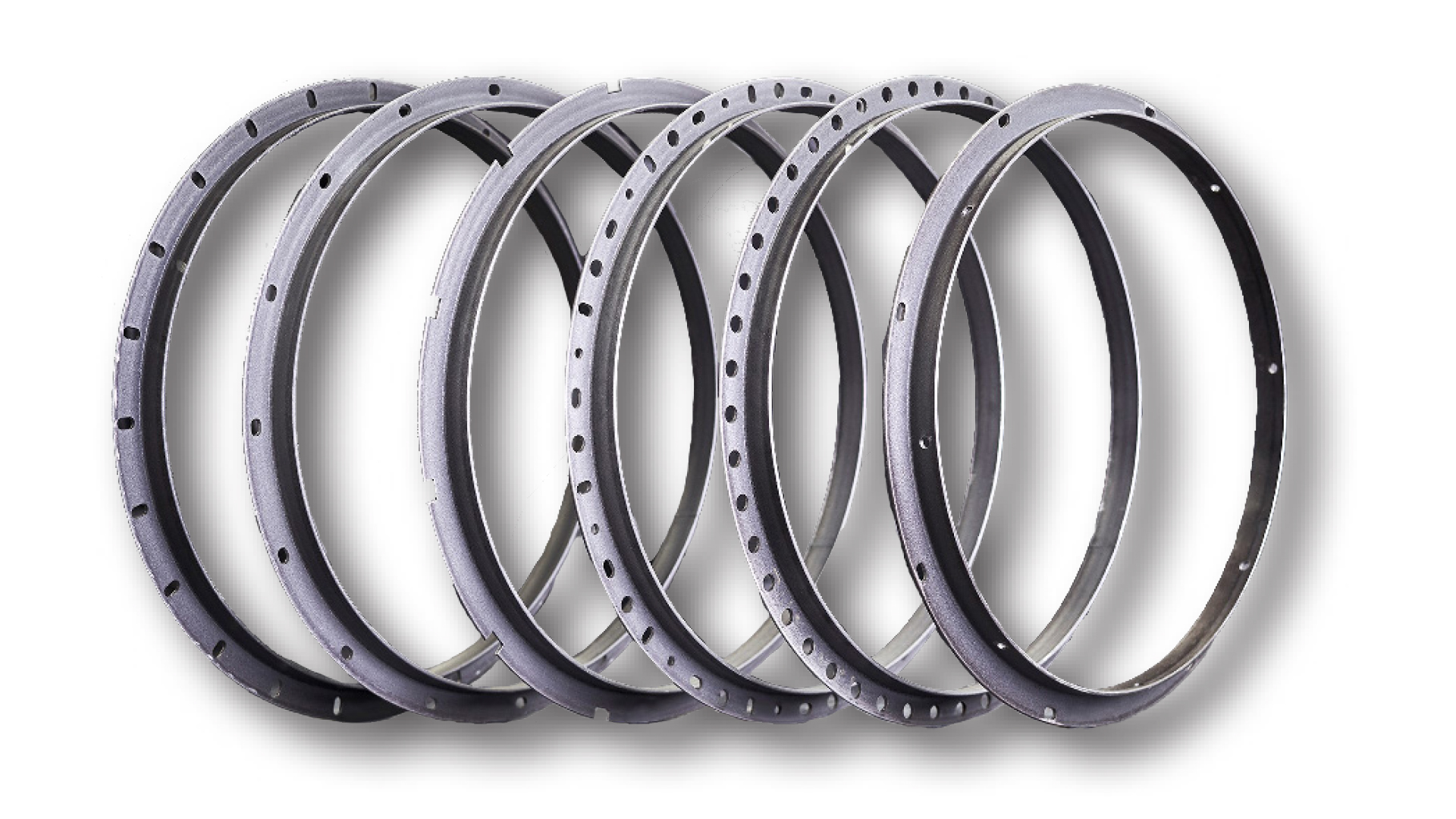

Round ANSI Wafer Style Butterfly Dampers

2000 SERIES – ANSI CLASS WAFER

2200 SERIES – ANSI FABRICATED WAFER

2500 SERIES – ANSI CLASS LUGGED WAFER

- Solid body wafer is designed to be bolted between Class 125/150 flanges. Optional 300, 600, 900, 1500 & 2500 Class flanges.

- Commonly utilized when narrow face to face applications is required.

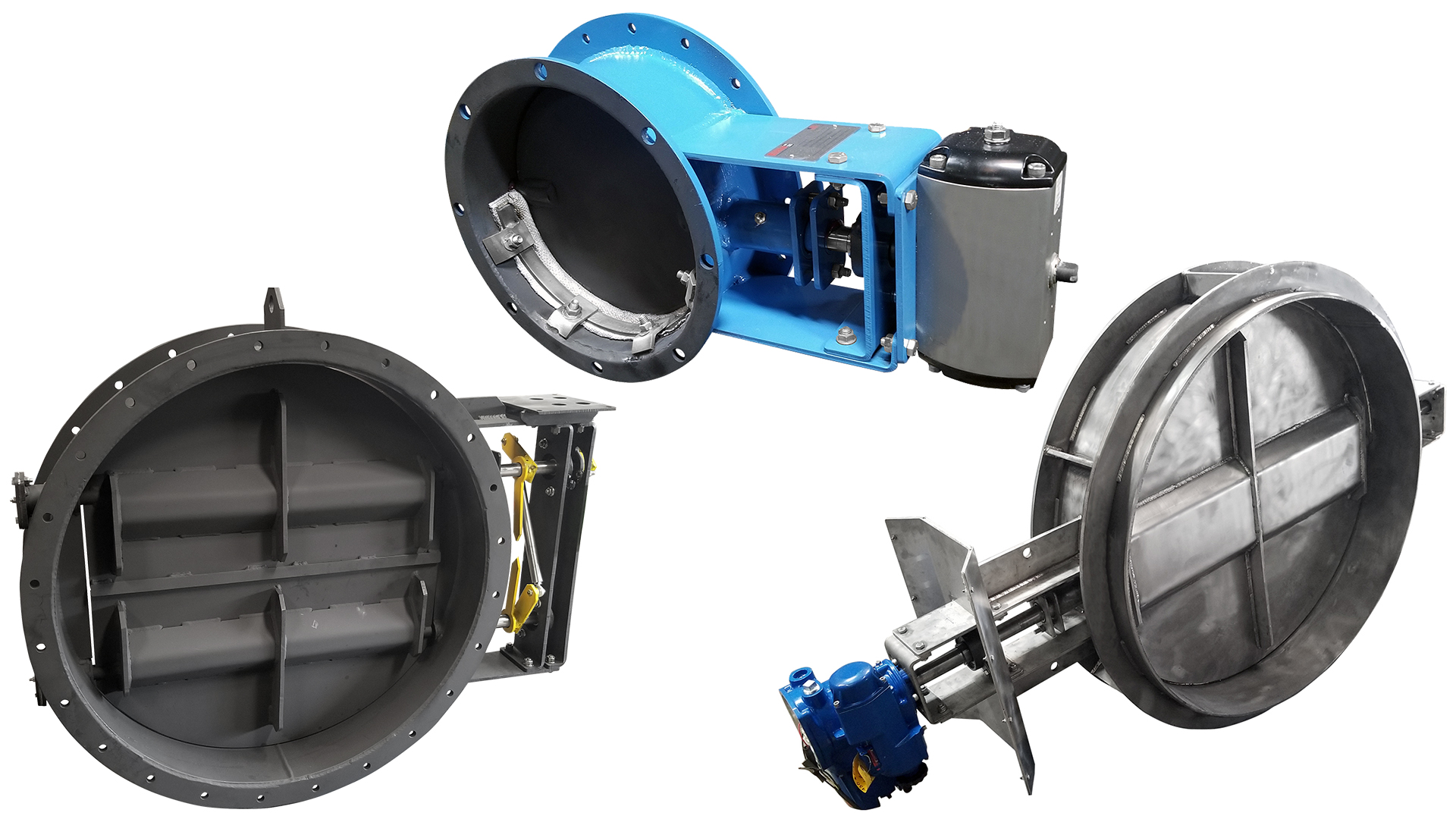

Round Butterfly Dampers

2100 SERIES – DUCTWORK DRILLED MEDIUM DUTY

2300 SERIES – ANSI DRILLED HEAVY DUTY

2400 SERIES – DUCTWORK DRILLED HEAVY DUTY

2700 SERIES – WELD-IN HEAVY DUTY

2800 SERIES – ROUND MULTI-LOUVER (Example)

- 2100 series utilizes rolled angle rings and is commonly used in HVAC applications.

- 2300 & 2400 series are commonly utilized in rugged service.

- 2700 series is commonly used in hazardous applications and comes standard with weld ends and optional 37.5˚ bevel. 3:1 taper and stub flanges available.

Diverter Dampers

2600 SERIES – TEE & WYE DIVERTER

- Commonly utilized in bypass applications.

- Main and branch angle, lengths, and diameter can be

individually customized to match any application. - Available in all flange/connection styles, including Weld-In.

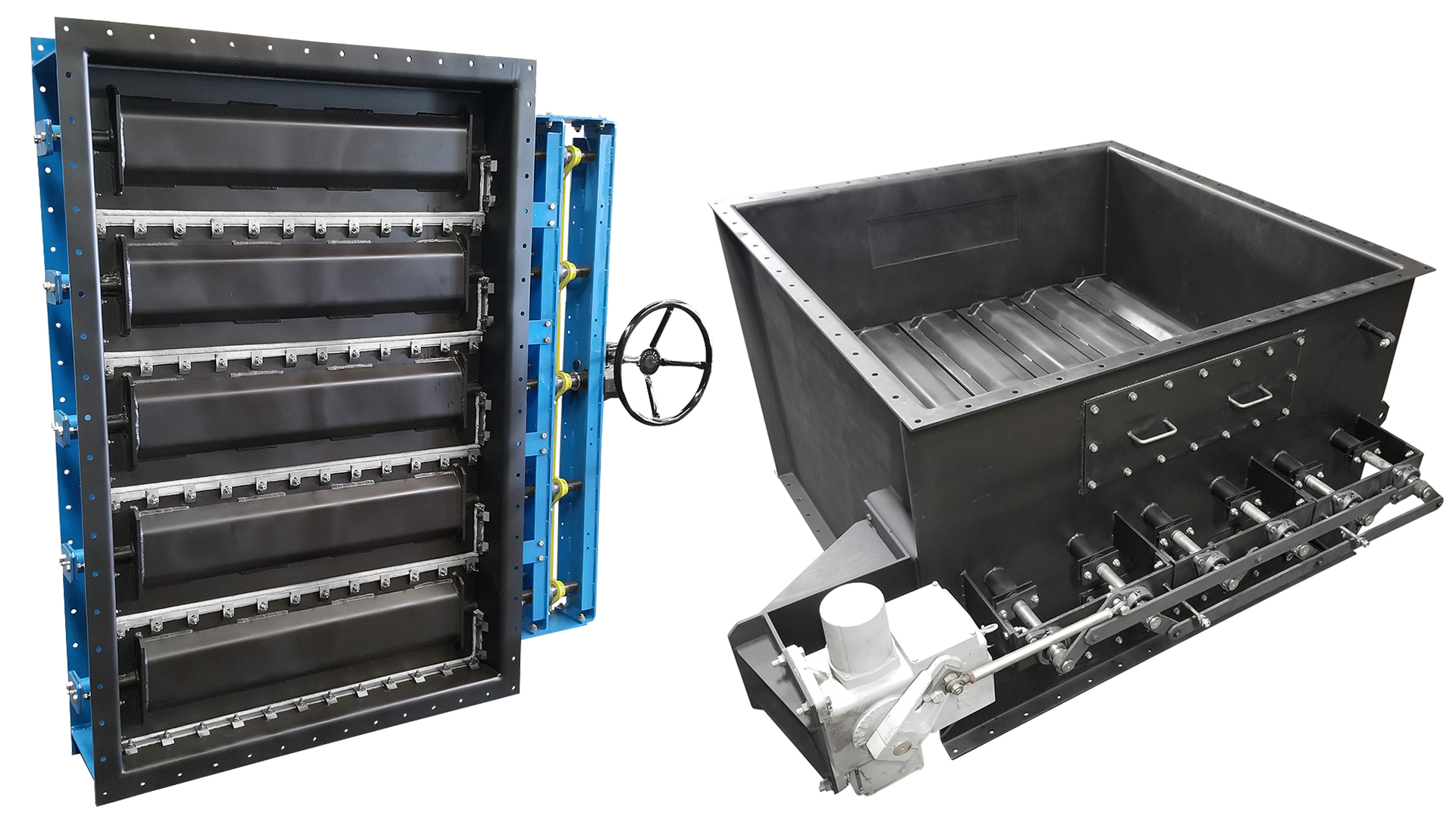

Square & Rectangular Butterfly Dampers

3200 SERIES – SINGLE BLADE

3400 SERIES – MULTI-LOUVER

- 3400 series can be configured with a varying number of blades for parallel or opposed operation. Available in all flange/connection styles, including Weld-In.

- Multi-louver dampers are often utilized to balance air flow and where ductwork size or configuration limitations prevent usage of a butterfly damper.

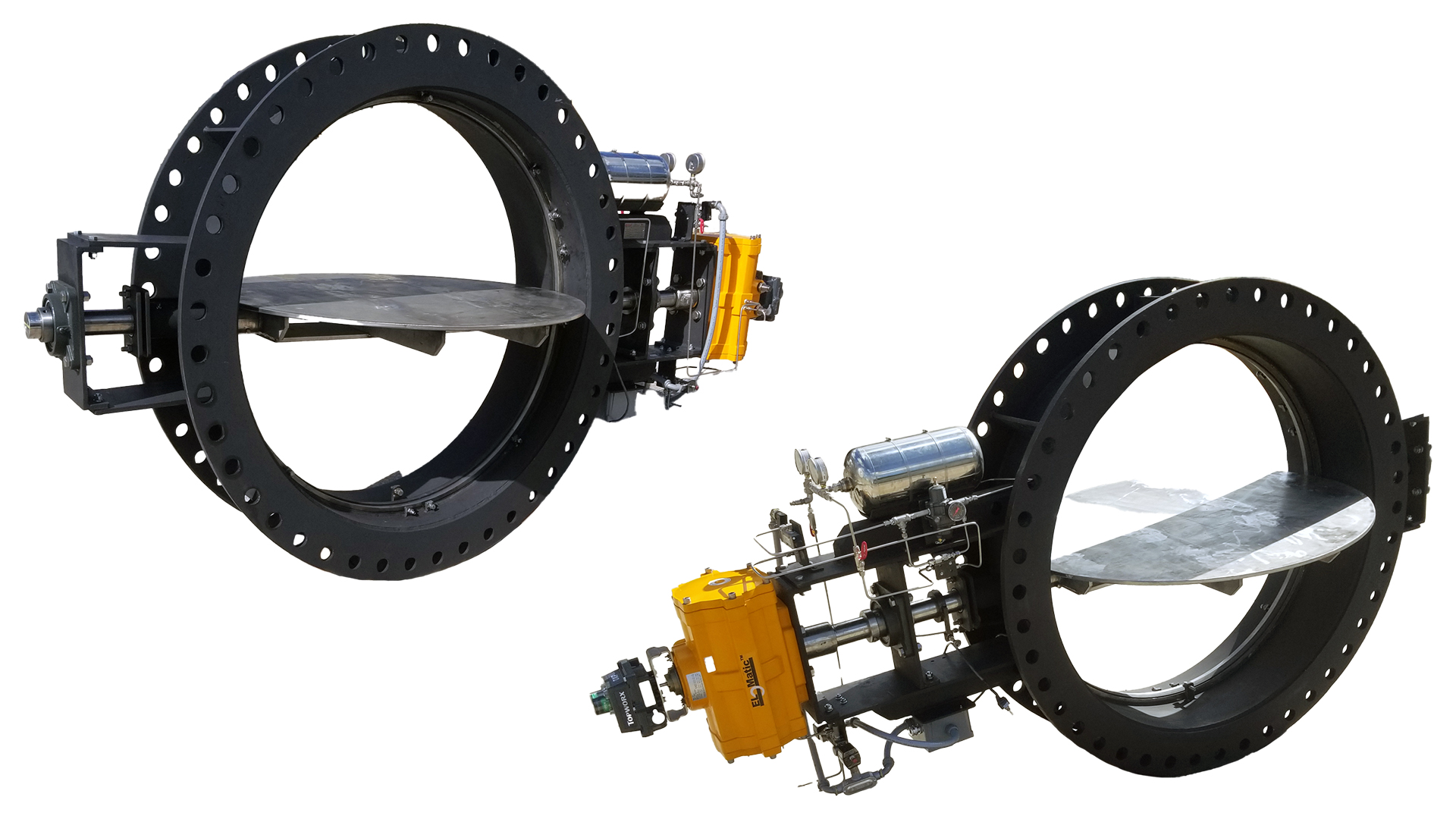

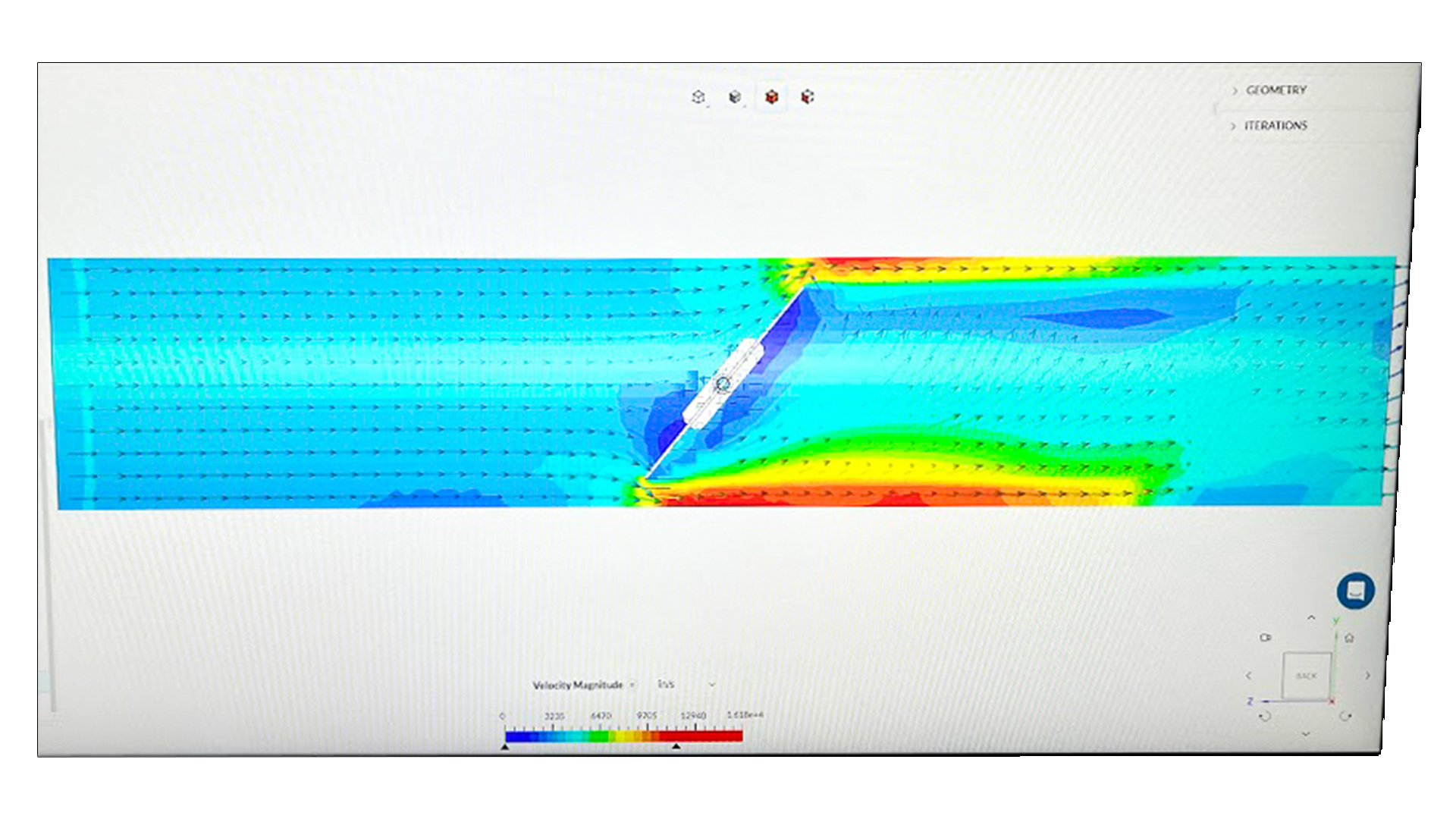

Zero Leakage Butterfly Valves

4100 SERIES – EV-O-SEAL™

4300 SERIES – FLATE-O-SEAL™ (US PAT. 3,840,208)

- 4100 series is a double offset, zero leakage shut off valve utilizing a disc edge against a machined tapered metal seat for applications reaching 425°F.

- 4300 series is a double offset, zero leakage shut off valve with inflatable soft seat that seals around the disc edge with a lower actuator torque requirement for applications reaching 425°F.

4400 SERIES – Monarch™ (Pat. PENDING)

- 4400 series is a zero-leakage shut off valve with a double shaft butterfly disc for applications reaching 1,800°F.

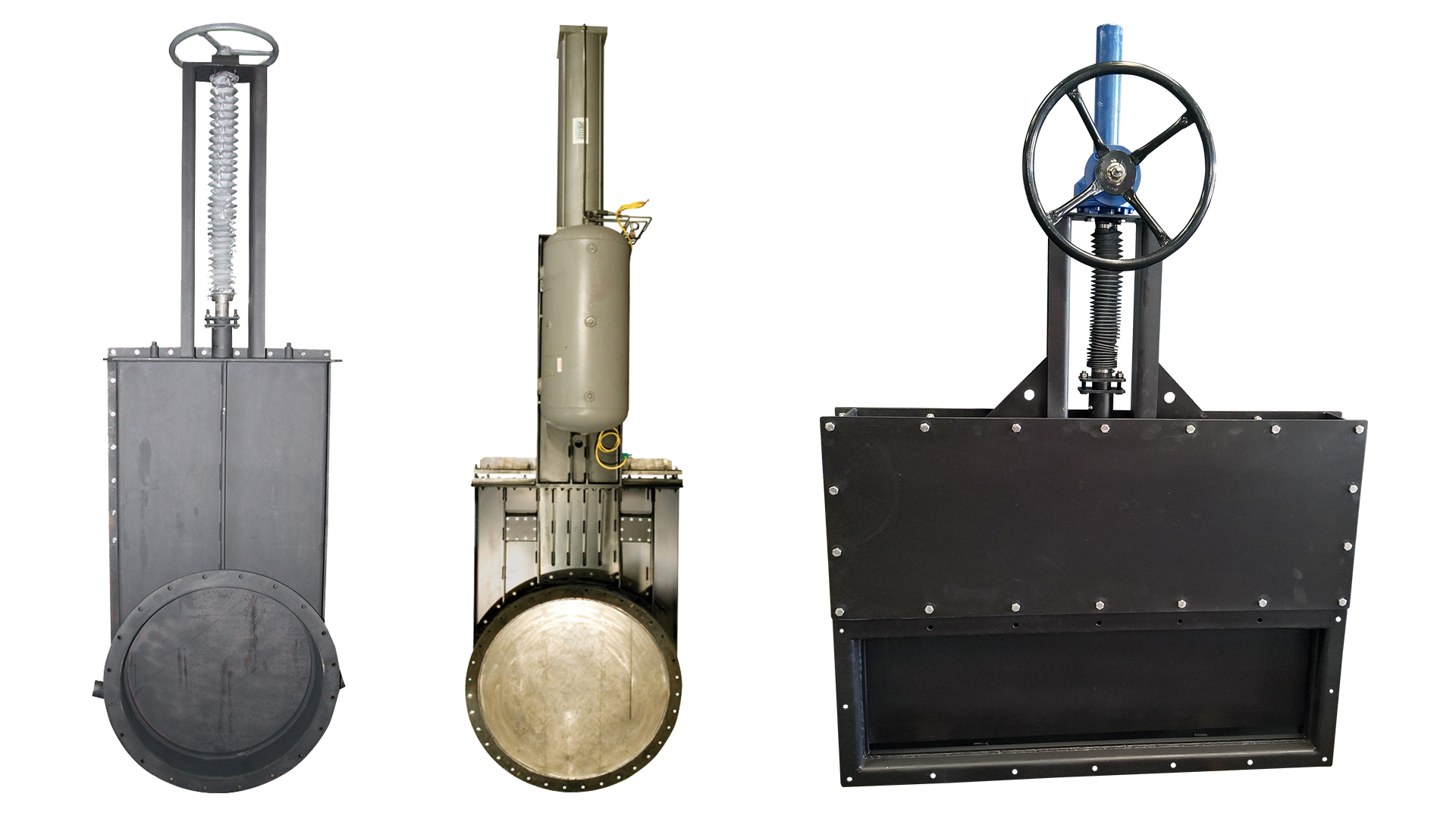

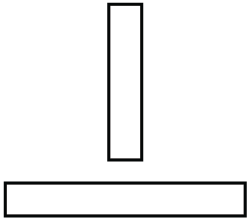

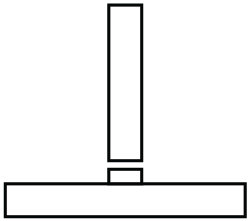

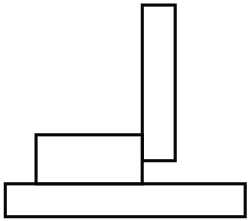

Gate Valves

5000 SERIES – ROUND GATE VALVE

5200 SERIES – SQUARE/RECTANGULAR GATE VALVE

- Available in all flange/connection styles and allow for minimal pressure drop across the valve. Commonly utilized to minimize flow resistance and turbulence.

Refractory Lined Round & Rectangle Dampers

- Most dampers can be configured with a fully cured refractory lining and water/ air-cooled wetted components for durable performance in high temperature applications.

- The refractory lining is a cost-effective alternative to expensive alloys for temperatures up to 2,500˚F. Additional information available upon request.

- Example of Elite’s Refractory Process

Damper & Valve Seat Options

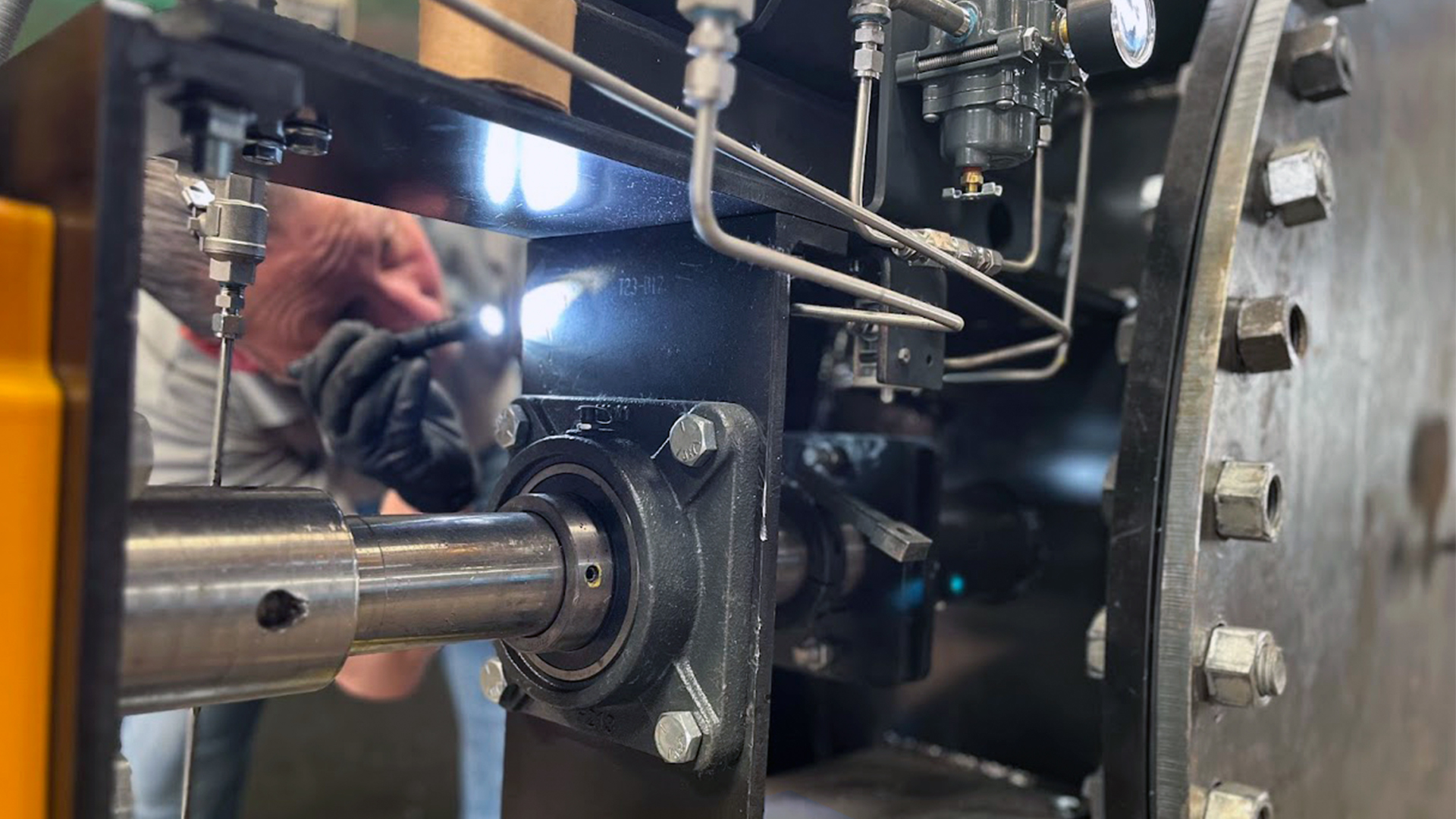

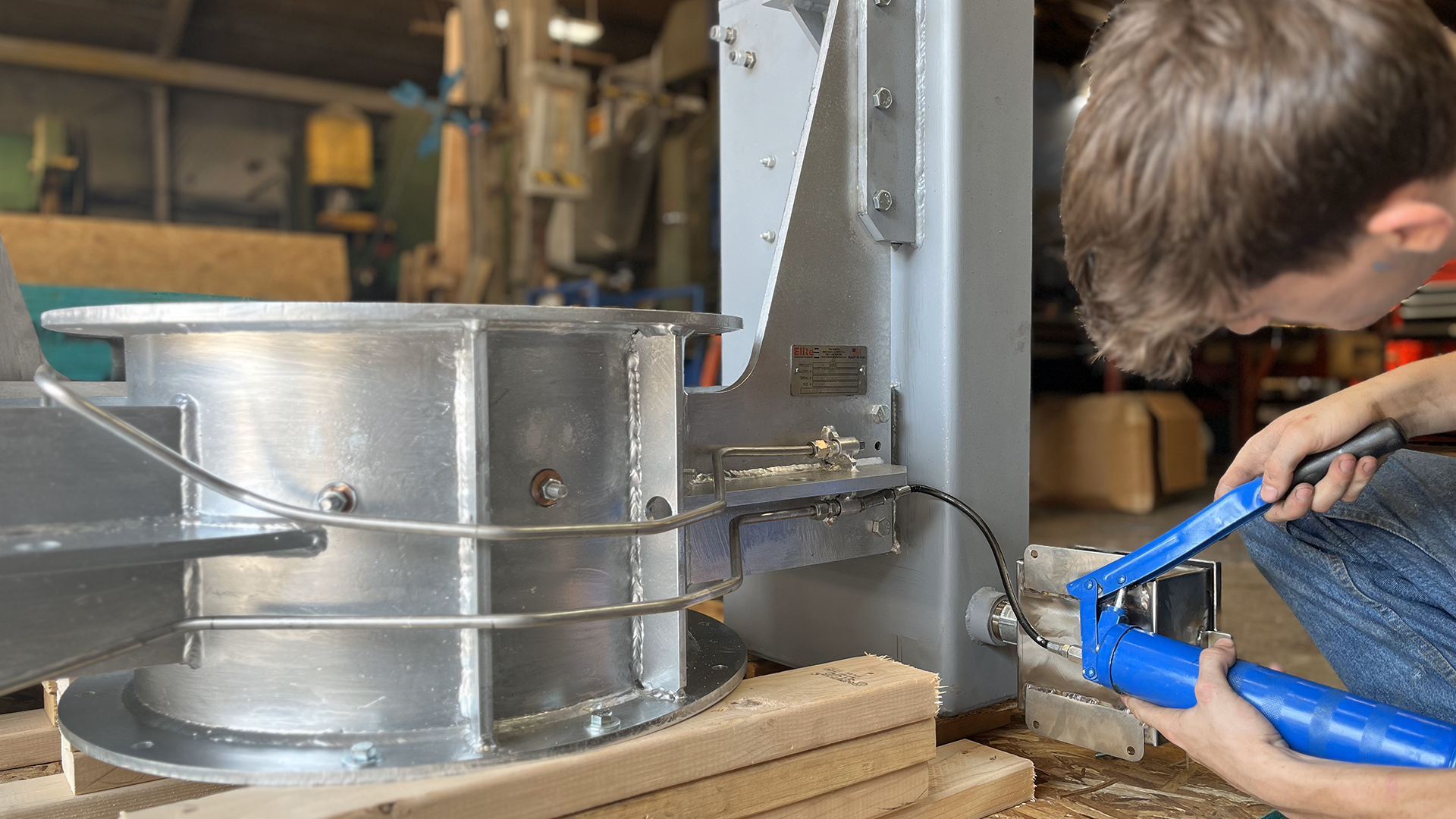

Automation

- Offering fully automated valves and dampers with optional self-diagnostic capabilities for enhanced performance monitoring.

- Expertise in Automation: Our Final Controls team specializes in mounting, programming, and testing various automation packages, including pneumatic, electric, hydraulic, and manual actuations.

- Testing and Customization: Operation test reports and Factory Acceptance Testing available upon request.

- We mount and test all types of actuators, including but not limited to those from Bettis, Rotork, Fisher, AUMA, Neles, Flowserve, Triac and J-Flow, among others.

- Bare stem dampers can be supplied with a custom mounting kit, which includes necessary shaft machining, adapters, and mounting brackets.

Testing Services

SERVICES AVAILABLE UPON REQUEST

- Weld Testing: X-Ray, Dye Penetration & Ultrasonic tests.

- Pressure Testing: Pneumatic and Hydrostatic pressure tests.

- Leak Testing: Air and Bubble Leak tests.

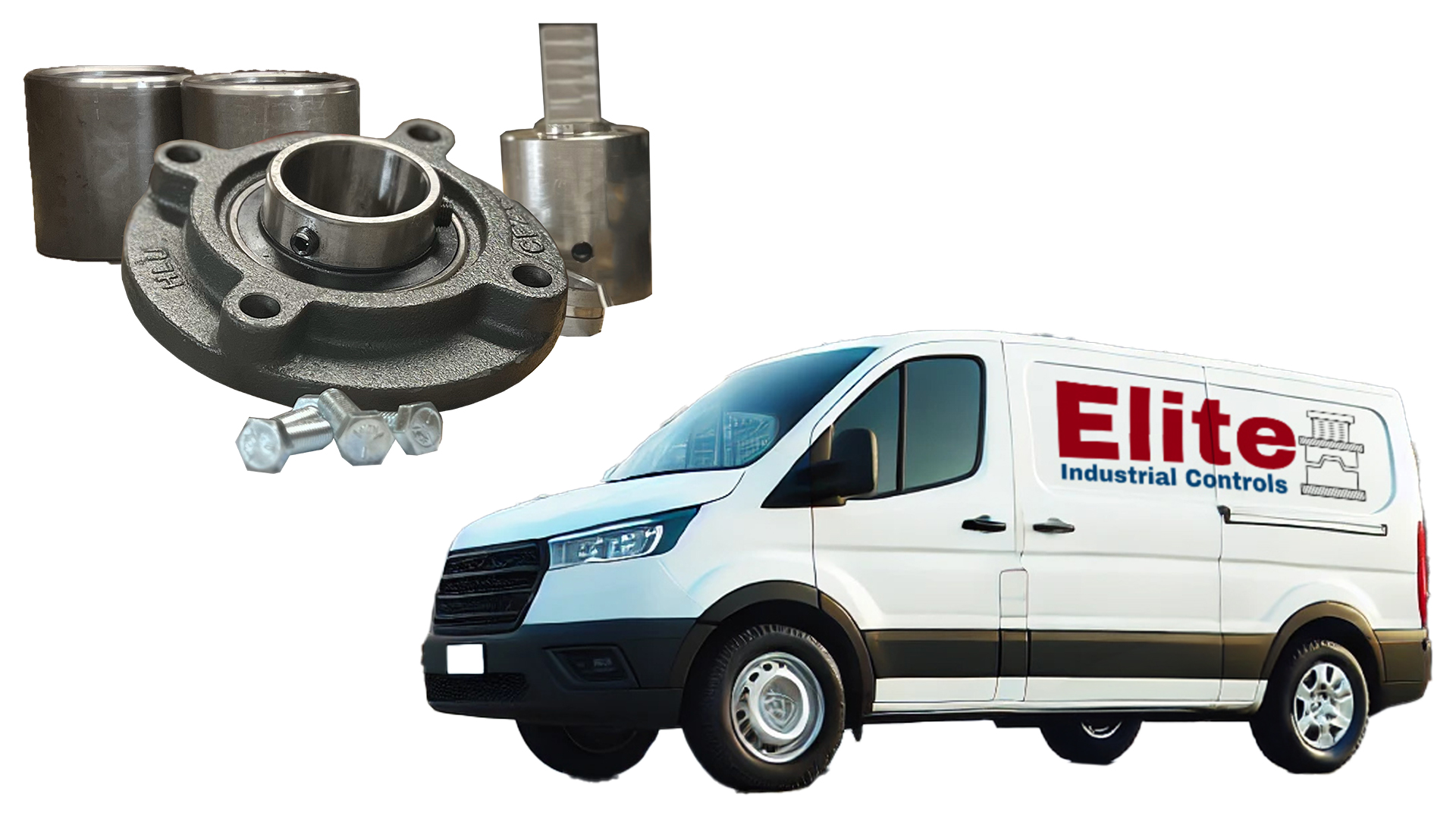

Complete Your Project with Elite's Turnkey Solutions

Popular Applications

- Heat Recovery

- Carbon Capture Systems

- Abatement Systems

- Thermal Oxidizers (RTOs)

- Blast Furnaces

- Bypass/Diversion Ducts

- Fresh Air/Ventilation

- Boiler Systems

- Purge & Seal Air Systems

- Electric Arc Furnaces

- Flue & Exhaust Gas

- Dryer Systems

- Pre/Re Heating Systems

- Dust Collection/Canopy Hoods

- Vacuum De-Gassers

Customized to Fit Your Application

- Damper Configurations: Sizes range from Ø4” to Ø144”, with larger sizes available upon special request.

- Fabricated bodies with rolled angle rings, ANSI drilled, or ductwork flanges. All dampers are produced with a bolt pattern of your choice as a standard.

- Available with any flange or connection style, including Weld-In options for diverse application needs.

- Flange Face: Options include flat-faced, machined, or serrated, as required by the application.

- Standard Shaft: Slotted, stubbed, and thru shaft connection styles available to be utilized based on service conditions and torque requirements.

- Stuffing Box Designs: Various designs are available to accommodate cryogenic to high-temperature applications.

- Materials of Construction: Options include Carbon Steel, 304 Stainless Steel, Inconel, Titanium, 253MA, and many more. Various soft seal materials are available to fit all class leakages at a variety of temperatures.

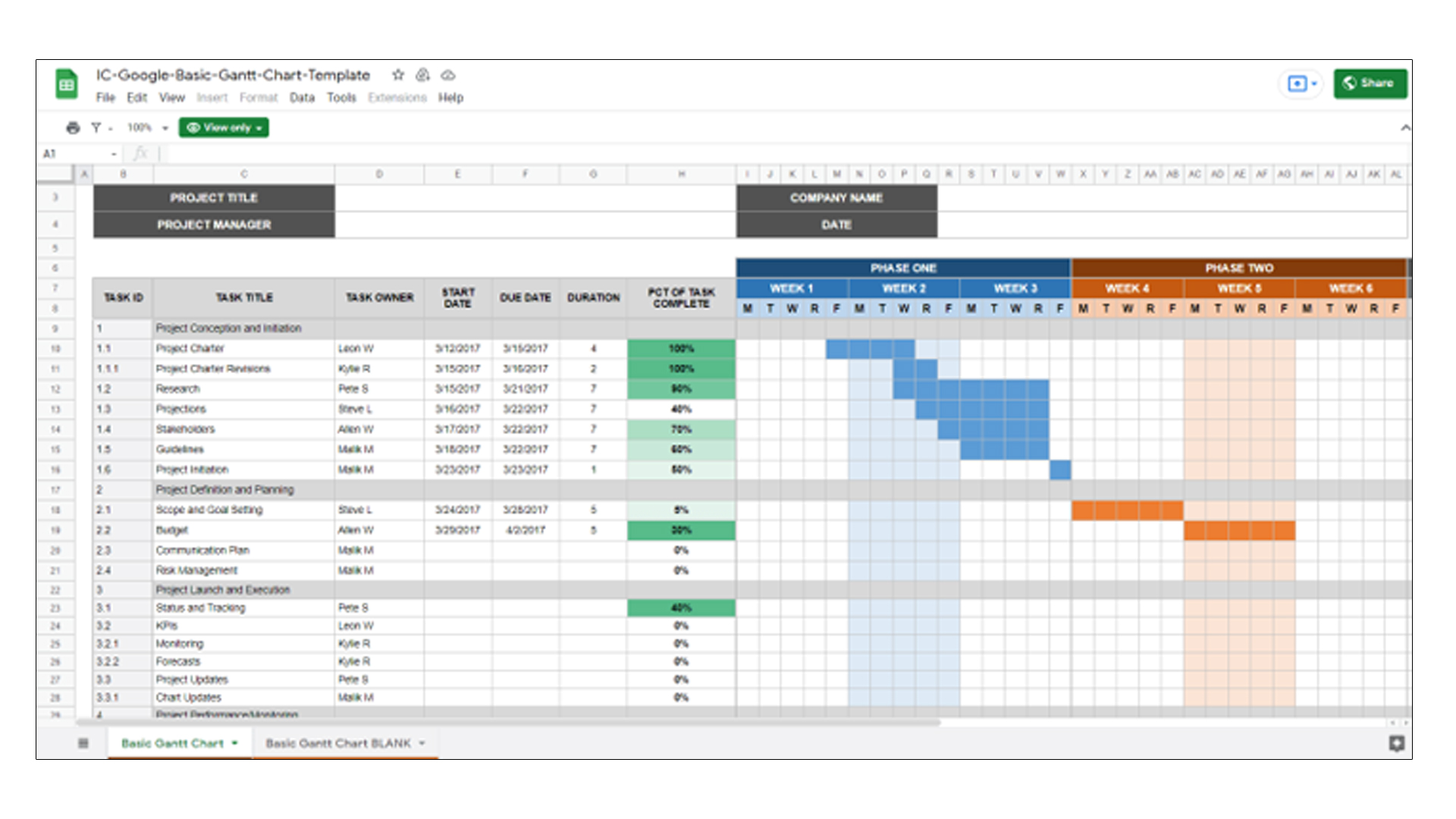

Engineering, Aftermarket & Field Service

Our mobile services are available on-site and on-demand to suit your project’s specific requirements. Our skilled technicians can assist with installation, calibration, start-ups, turnarounds, and aftermarket repairs, either at your location or ours, depending on what’s most feasible.

Initial Engineering Collaborations and Consultation:

- Collaborative planning and walk-through sessions to align on project goals, ensuring efficient execution and tailored solutions from the outset.

Installation and Calibration:

- Setup and fine-tuning of equipment to ensure optimal performance from day one.

Service Contracts:

- Proactive and strategic maintenance contracts to minimize downtime and enhance productivity.

Aftermarket Repair:

- Comprehensive support to maintain and extend the life of your equipment, with convenient pick-up and delivery options.

Factory Inspection, Service & Repair

At our vertically integrated facility, we conduct thorough evaluations and repairs, utilizing advanced testing and fabrication equipment. Our highly trained technicians are dedicated to delivering top-tier service, including on-site re-installations. We exclusively use OEM parts from certified vendors and strictly adhere to the highest industry standards for calibration and configuration.

Disassemble, Clean, and Refurbish:

- Complete overhaul of your existing equipment to restore and enhance its performance regardless of the manufacturer.

Testing and Quality Assurance:

- Every refurbished item is thoroughly tested through our 80-point inspection to meet stringent quality standards before re-installation.