Check out our latest engineering development that addresses the need to meet stringent environmental regulations: our heavy-duty ductwork drill flanged dampers, specifically designed for 𝐑𝐞𝐠𝐞𝐧𝐞𝐫𝐚𝐭𝐢𝐯𝐞 𝐓𝐡𝐞𝐫𝐦𝐚𝐥 𝐎𝐱𝐢𝐝𝐢𝐳𝐞𝐫 (𝐑𝐓𝐎) applications.

𝐖𝐡𝐲 𝐝𝐨 𝐰𝐞 𝐞𝐧𝐠𝐢𝐧𝐞𝐞𝐫 𝐚𝐧𝐝 𝐦𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐞 𝐭𝐡𝐞𝐬𝐞 𝐝𝐚𝐦𝐩𝐞𝐫𝐬?

We understand the critical role RTO systems play in helping industries comply with environmental regulations. To support this, we engineered dampers with features that enhance performance and reliability:

🔧 𝐄𝐥𝐢𝐭𝐞 𝐇𝐲𝐝𝐫𝐚𝐮𝐥𝐢𝐜 𝐀𝐜𝐭𝐮𝐚𝐭𝐢𝐨𝐧: Inside an Elite manufactured NEMA 3R enclosure, our hydraulic actuation system ensures smooth and precise operation, even in challenging conditions. This means less downtime and more consistent performance for your RTO systems.

⚙️ 𝐀𝐝𝐣𝐮𝐬𝐭𝐚𝐛𝐥𝐞 𝐒𝐞𝐚𝐭: Flexibility is key in optimizing flow control. Our adjustable seat design allows for precise adjustments, improving overall efficiency and adaptability in various settings.

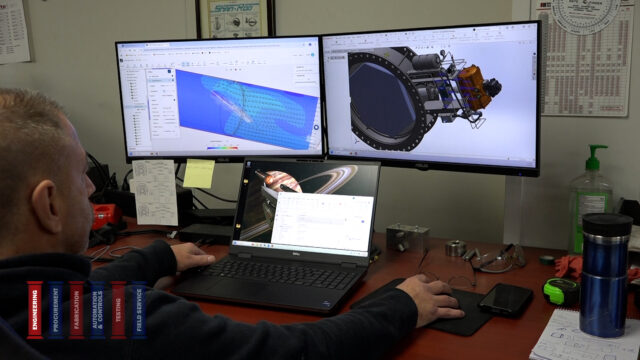

🏭 𝐈𝐧-𝐇𝐨𝐮𝐬𝐞 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠: We are proud to manufacture both the damper and the enclosure at Elite. This integrated approach ensures the highest quality and reliability, giving you confidence in the products that support your mission to meet environmental standards.

🌐 𝐄𝐧𝐡𝐚𝐧𝐜𝐞𝐝 𝐂𝐨𝐫𝐫𝐨𝐬𝐢𝐨𝐧 𝐑𝐞𝐬𝐢𝐬𝐭𝐚𝐧𝐜𝐞: Our dampers are built with materials and coatings that provide superior corrosion resistance, ensuring long-term durability and performance in harsh environments.

𝐎𝐮𝐫 𝐠𝐨𝐚𝐥 𝐢𝐬 𝐬𝐢𝐦𝐩𝐥𝐞:

to provide solutions that help you achieve compliance with environmental regulations more effectively and efficiently.