Elite Industrial Controls will provide all of our customers with continued support to get their application functional. One of our recent projects was helping a major steel producer repairing a large Ø120″ valve during their initial shutdown for 2021. We were able to receive in, inspect, repair and return in a few weeks to be reinstalled in-line before the return to production. Our engineers thoroughly inspect form, fit and function of the issues in question from the customer. This includes replacing service & wear parts including but not limited to bushings, packing, bearing(s), replacement seats (metal or tadpole) and/or actuation.

The valve was originally manufactured in 2014 and has been in-line during the production of mass steel manufacturing since. When the valve was received in some noticeable damage was visible based on the usage of the valve. Extensive work was going to be needed to get the valve back up and functional in-line.

One noticeable damage was that of the disc hub and part of the shaft were corroded and deterioration from the constant beating from iron dust being moved through the valve at a steel plant. The disc was in good condition so the disc hubs would need to be cut out along with the connecting shafts.

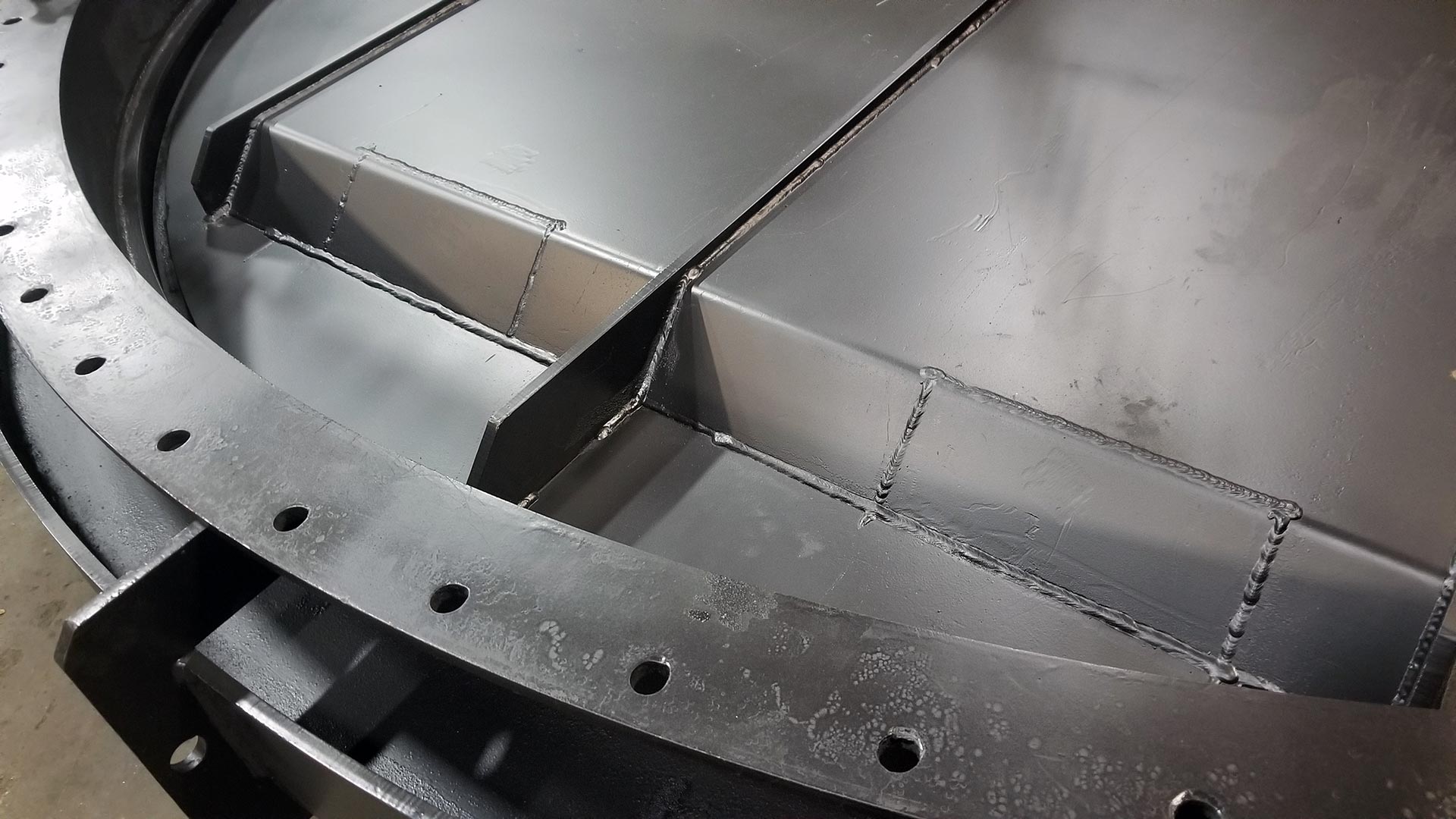

Another issue seemed to develop overtime based on the stitch welded disc reinforcements. With each part of the reinforcement not being fully welded the iron dust slowly forced its way inside the airfoils on the disc. This caused additional weight and strain on both shafts and actuation. The additional weight to a Ø120″ valve disc made it difficult for the actuator to perform successfully and the extra strain on the shafts caused the disc to touch the inner body on full close. This is why it’s important to mention all project details of use when having the valve originally designed.

With the customers shutdown occurring within the next few weeks of receiving the valve for inspection we were quick to turn around a repair summary and quote to move forward.

Once we received in the purchase order we went to work fixing the following:

- Remove the disc and cut top of airfoils to remove solidified metallic dust.

- Replace and fully “seal weld” airfoils to disc.

- Cut out and replace disc shaft hubs.

- Remove shafts and upgrade with a 17-4PH Stainless Steel material.

- Upgrade stuffing box bushings from Carbon to Nitronic 60 along with new packing material.

- Drill shaft disc hubs and pin using matching new 17-4PH taper pins & fabricated new hubs.

- Fabricate and replace bearing mounting/actuator plate on power side and bearing plate on blind side using piloted bearings.

- Fabricate and mount blind side limit switch brackets and attach with carbon steel lever arms for proximity sensors.

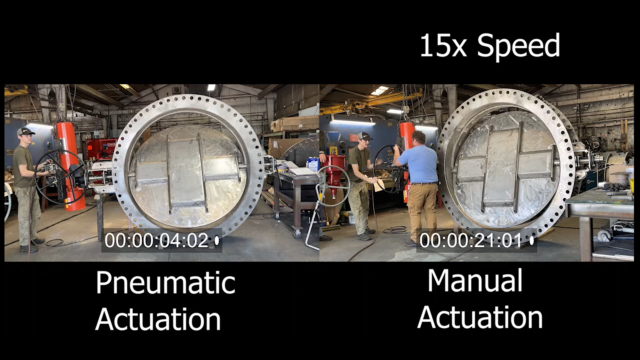

- Reassemble disc assembly to the valve body and test by manual 90° stroke open/close.

- Finally clean and touch up with paint before shipping back to the customer.

We were able to turn around the fully repaired valve in less than a week meeting their shutdown window. The customer was satisfied with the repair when the window of replacement was too small for a complete new valve to be built. Not to mention being cost efficient of repairing a valve in solid condition than to start from scratch!