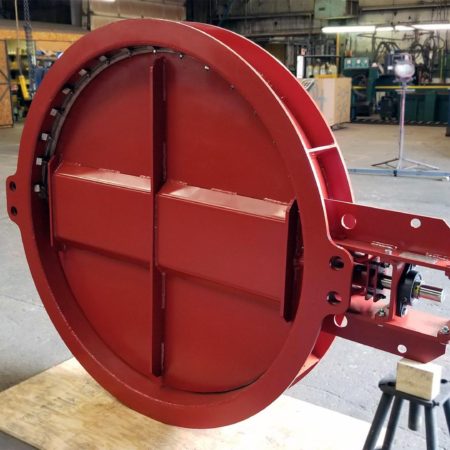

Elite Industrial Controls offers various valve and damper designs to fit our customers wide range of applications and project needs. Our 2600 diverter series offers two styles: tee & wye. Our standard tee diverter is shaped in exactly what you expect, T shaped. For more unique projects we offer a wye diverter option in any degree offset < than 90° (45° shown in example). We can customize the design to fit an existing line or completely new installation.

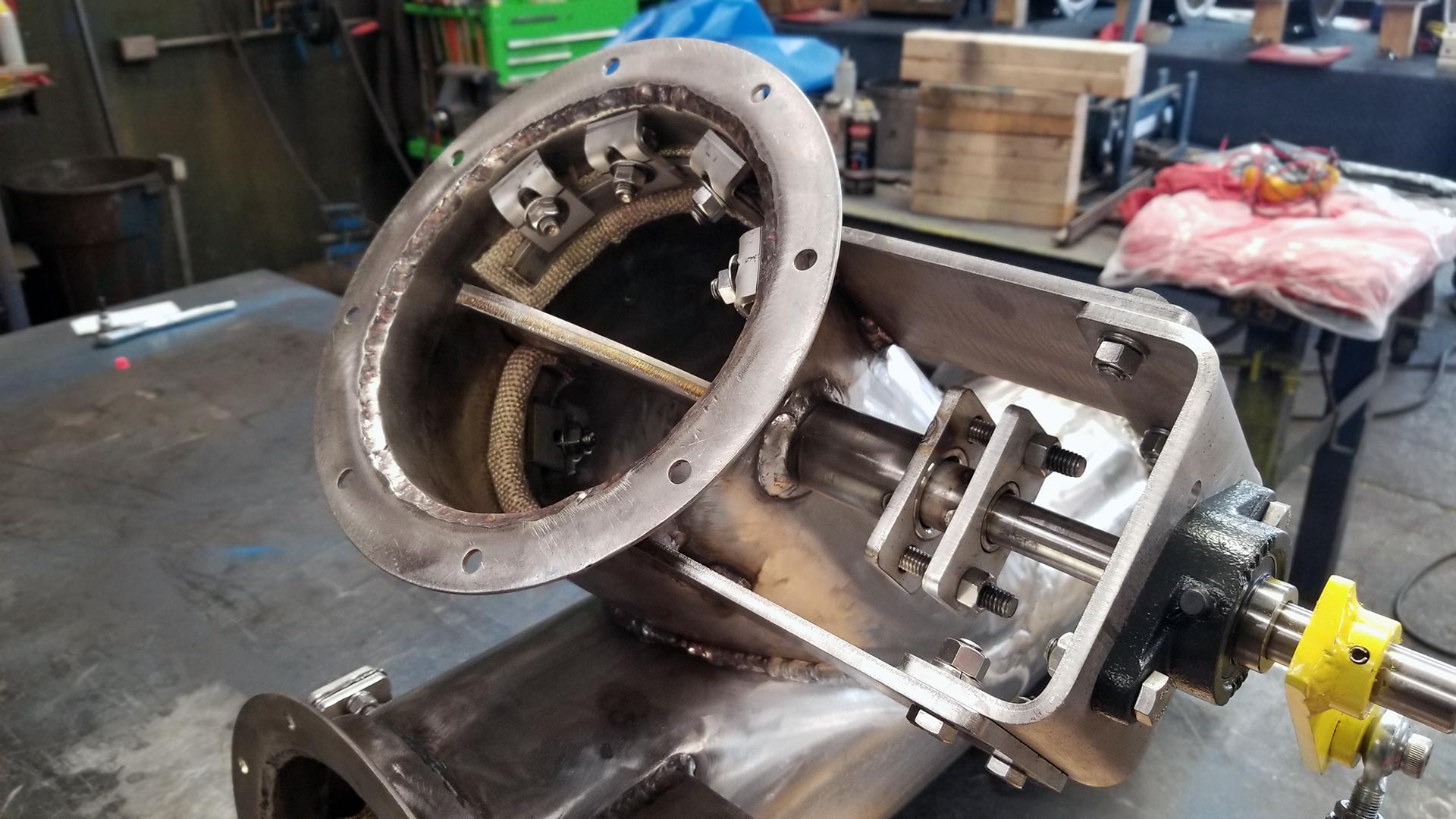

The wye diverter design is unique compared to our other series because it allows a tighter fit of flanges and pipe run with the diverter being as close as possible to one side of the pass through without disrupting connection. We can design a diverter to fit any sized diameter required for your application. In the example shown we have a Ø8″ model 2620-8(Y)-8(Y), 2600 series wye diverter w/ rotary actuation & tadpole seat.

For this application Ø1/2″ tadpole seat was used to allow only 1% estimated leakage at maximum capacity. Every tadpole seat used at Elite is graded to withstand high temperature and assembly includes 304 stainless steel retainer, clips, nuts and washers. 304 SS ensures the internal hardware can withstand the required temperature without fail. This is even performed on carbon steel valves/dampers to guarantee function long before any carbon on the valve/damper would need to be repaired/replaced.

Each flange input has associated stuffing boxes with power side mounting brackets. This includes a ball bearing with a linkage arm connecting both shafts together to move in unison. Each side of the linkage arm is connected to a shaft collar that is drilled & pinned directly to each shaft. This is key in our diverters to work flawlessly.

Our wye diverter is a perfect solution when you need to distribute media to a different flow than a direct shutoff. We can design a diverter of any size needed to complete your unique application. Elite can customize an actuation package to satisfy the torque requirements to open/close as well as the actuator type: hydraulic, pneumatic, electric, etc.